|

|

|

|

Flaws, Issues & Risks Synthesis Tool (FIRST) System

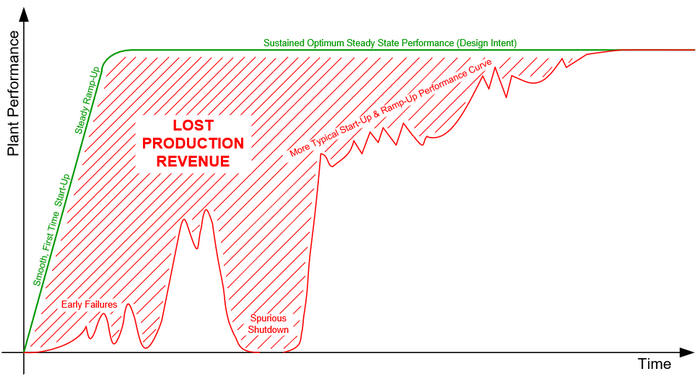

The Flawless Concept The graph below illustrates the difference between the desired performance (specified in the design) and the typical performance of many (if not most) projects.

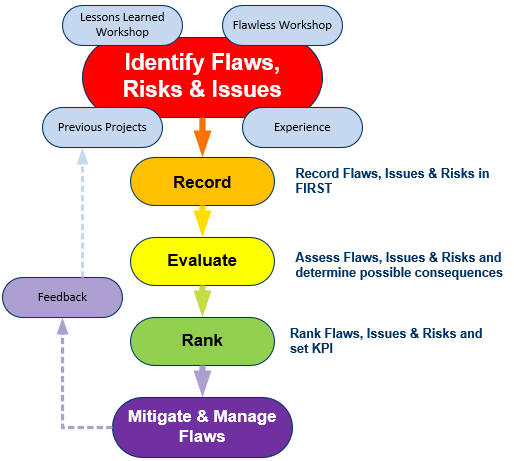

Ideal vs. Typical Performance Graph The idea of implementing a process to circumvent these problems was developed into a process which was unfortunately given the name 'Flawless Start-up', and therein lies the first problem. The immediate impression given by the name, infers that it is a process that can be deployed during start-up, whereas in truth, many of the issues that detrimentally affect the start-up of an asset, originate in the initial concept, the design and construction activities and it is too late to resolve them at the commissioning and start-up stage. In the OR&A™ Solution however, this idea has been modified to introduce the 'Flawless' idea at the earliest stages of a project, such that these issues can be identified and resolved or mitigated before they have a detrimental effect on the project. The 'Flawless Project Initiatives' or 'FPI' concept is embedded in the OR&A™ Solution as a core Subject. To support the deployment of the FPI process, the OR&A™ Solution has an integrated tool which is used to manage the process. The Flaws, Risks & Issues Synthesis Tool (FIRST) enables the identification, evaluation and management of Flaws, Issues and Risks throughout the life-cycle of the project. Coupled with the FPI Activities detailed in the OR&A™ Solution FPI process and through a series of posters, short hands-on toolbox talks and practical advice (rather than PowerPoint presentations) intended to reach the main target audience, i.e. the people actually doing the work.

Flawless Project Initiatives In current projects, the construction process is primarily driven by the schedule which in itself is driven by cost. This is directly at odds with the higher level objective of the Operations Team who, in addition to receiving an asset on-time and under budget, need to receive an asset which can be operated at the design intent parameters, to generate revenue from the product produced and thereby repay the investment made at FID in the shortest possible time, in other words addressing the Total Cost of Ownership. The Flawless Project Initiative (FPI) concept promotes the necessary attention to detail during construction to ensure the quality of the construction activities. This is achieved by implementing a number of strategies to ensure that the integrity designed into the asset is maintained through construction and is continued into the OPERATE phase. Many projects have found that, rather than add cost or increase the schedule of a project, doing things 'Right First Time', actually reduces costs and often improves the schedule, by avoiding needless repetition of work done badly or early failures due to poor (often hurried) installation of equipment. The Flawless Project Initiative (FPI) concept is a key element of the OR&A process. The aim of FPI is essentially to ensure a smooth, first time start-up of the asset, followed by a steady ramp-up to sustained optimum performance at the design intent. FPI is also a key enabling process for successful project delivery. It is intended to ensure a structured and timely execution of activities that lead to a ‘right first time’ start-up and subsequent stable and sustainable operations and maintenance of the completed asset. The first step in employing the Flawless Project Initiative (FPI) concept is to secure the commitment of management to the FPI process and ensure it is captured in the necessary project documents (philosophies, strategies and plans). Clear commitment of Senior Management from the earliest stage of the project development process is essential for FPI because of the potential contractual implications. There is, for example, a direct contradiction with the idea of giving additional incentives for early start-up of the facilities, when doing so may not be in the best interests of the facilities themselves. The FPI process also identifies and assesses the risks to the Flawless concept and seeks to implement appropriate mitigation measures at the appropriate time.

Flaws, Issues & Risks

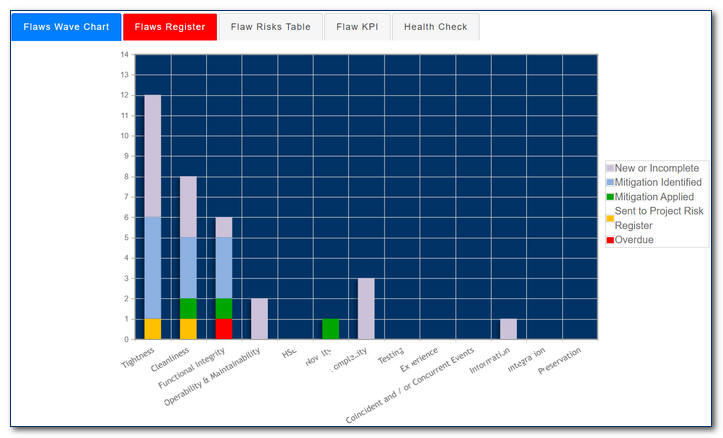

Synthesis Tool (FIRST) The FIRST system removes this drudgery and manages the entire process automatically, thereby applying the required robustness and rigidity. FIRST is hosted on the same cloud server as the OR&A™ Solution, is accessed in the same way and offers much the same functionality, albeit for the FPI Process. The interactive screens and dashboard displays in FIRST enable the user to navigate easily through the system and to record, monitor and manage Flaws in a consistent and robust manner. The system generates the necessary reports and output required to keep the Project Team informed.

Flaws, Issues & Risks Synthesis Tool (FIRST) System

Identifying and Managing

Flaws Mitigating action is recorded and the status displayed on the Flaw Record and Flaws Wave Chart.

Flaws Wave Chart The Flaws Wave Chart displays the current status of all Flaw Records in the system and clicking on a coloured segment of the Flaws Wave Chart opens a dialog window with a list of hyperlinks to the relevant Flaw Records.

Flaws, Wave Chart

The 'TABS' across the top of the

Flaws Wave Chart screen enable the user to access the relevant pages

required to implement, manage and monitor both Flaws and the the FPI

process. More information about the FIRST Tool and the Flawless Project Initiatives is available from OR&A™ Ltd. upon request. |

|

|

© OR&A™ |